If you don’t know, an outboard engine can cost anywhere from $9,000 to $80,000! So having an outboard engine failure can cost a ton of money!

Outboard Engine Failure: The Catastrophic Failures. There are two main catastrophic outboard engine failures that can happen. Either the lower unit or gear case blows up. Or the engine powerhead blows.

Here are the main factors and causes which result in the most expensive and catastrophic outboard engine failure.

Lower Unit or Gear Case Failures!

When a lower unit fails, this is usually a catastrophic failure because, without the lower unit, your boat isn’t going anywhere!

You are talking about being stranded on the water with no way of moving the boat. If you have a single-engine boat.

Another reason that it is catastrophic is because of the price tag that accompanies the gear case. Depending on what type of a failure you are talking about having.

Of course, there are some cost-saving routes that you can take when it comes to dealing with a blow lower unit.

You really have a couple of different options when it comes to how to fix a bad, blow, or failed lower unit.

But this will be determined by what type of failure we are talking about. And you’ll want to think about why an outboard gearcase fails in the first place!

Why Lower Units Fail

When a gear case grenades. This is generally due to one of three possible failures.

One, there is a manufacturer defect. Two there is a component failure. Or three, lack of lubrication leads to a failure. Aka a seal fails and the lower unit fills in with water.

There is one major way to avoid having to deal with this issue though. And that is going to be by routinely servicing your lower unit!

The color of the gear lube (read this article that tells you what the different colors mean.) Is going to tell you a lot about what is going on with the lower unit, a little bit ahead of a failure.

Here is also an article about outboard maintenance, the intervals, and some ways to save some money!

Servicing the lower unit will show you all kinds of things about the lower unit. It’s the only sign and first-line defense against a blown lower.

The first reason that a gearcase can fail is because of a manufacturer defect. This usually only applies to new lower units.

Or fairly new, lower hours lower units. If you have a gearcase with 1,000 hours on it, most of the time one of the other reasons is why it blew up. Not a manufacturer defect.

The second reason is going to be a component failure. Which is going to be a gear, a bearing, one of the shafts, or something else that just gives up.

But, a good amount of the time components fail because of lack of lubrication!

Usually, a failed seal allowing water to get into the lower unit, will not give proper lubrication to certain parts. Which will allow for friction and heat to build up.

Then it’s just a matter of time before the gear case grenades!

Now another reason that a component will fail. Is because of hard shifting! (Here’s an in-depth article about hard shifting boat engines!)

If you have a shifting issue and every time you go to shift the lower unit. The gears are hard grinding together.

This will create high stress and unnecessary wear on the gears in the lower unit.

Which will create a premature failure of the components!

So the best way to avoid an issue with a lower:

- Is going to be to make sure that you are shifting correctly!

- As well as servicing the lower unit on a regular and consistent basis!

But when it comes to having a blown lower unit, can you rebuild it, or is it just a replacement thing?

Lower Unit Replacements & Rebuilds

With the price of components, and the cost of labor. There are fewer and fewer places that are actually rebuilding lower units these days.

On average, the time that it takes to rebuild a lower unit can range from 4-8,10, or even higher depending on the lower unit.

Just to rebuild it properly, get it all apart, clean all the components, reinstall everything with new components, and check everything out.

The cost for labor alone can range at $100 per hour from $400 to over $1,000! And that doesn’t include taxes or parts!

Because of this, the shops that used to be able to rebuild the lowers, aren’t rebuilding them anymore.

When the average cost of an aftermarket lower unit can range from $1,000-$3,000 depending on what size and type of lower unit you are looking for.

Then it only takes 1-2 hours to just remove and replace the lower unit and get you back on the water.

This has made the rise of more aftermarket companies producing lower units. With the two most prominent companies being SEI, Crowley Marine, and OBR.

The cost of a brand new OEM lower unit can vary from $2,000-$9,000! Depending on what lower unit you are buying.

From a 2.5 horsepower engine to say a 425 horsepower engine. The price of the OEM can get really expensive!

But this is what does keep a few shops in the game of rebuilding these units, giving you an option to save a few bucks on certain occasions!

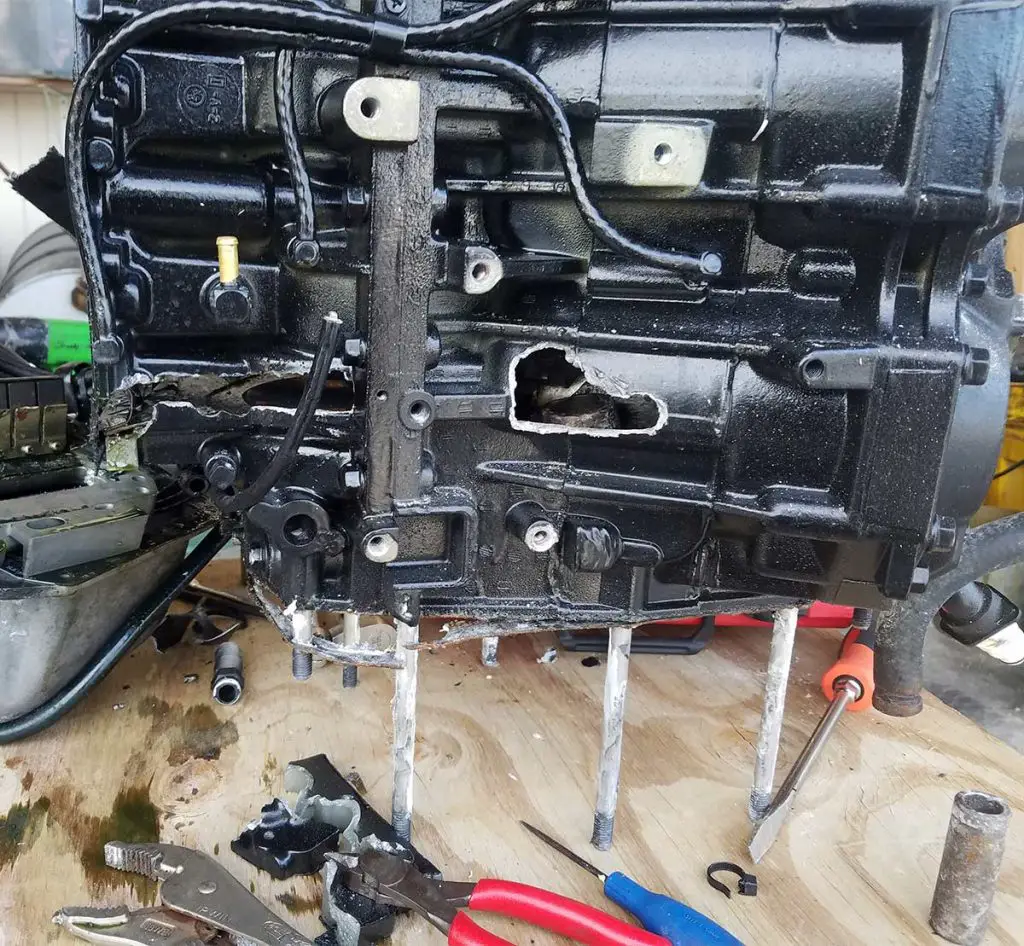

Symptoms Of A Blown Powerhead!

The other catastrophic outboard failure is going to be a blown powerhead! How do you tell if a boat motor is blown? What does “blown engine” mean?

These terms might be new to you and might sound a little unsettling. But that’s probably why the term is so popular. Because when a powerhead blows.

You are done and dead in the water. If you are unfamiliar with what a powerhead is exactly, you can read this article here that talks all about it!

A blown powerhead simply means that the engine has failed internally and mechanically.

And the symptoms of a blown powerhead and how you tell if the motor is blown can be misleading.

When the powerhead blows, that means that the inside has mechanically failed, valves, pistons, crankshafts, piston rods, or even the block itself.

These components have been destroyed and are not fixable, even to the point of being non-rebuildable!

Leaving your symptoms or signs to be something that can lead you to misdiagnose an issue with say a spark plug or fuel, to be a blown powerhead.

You are going to find the engine to not start, not spin over, be locked up: like the flywheel will not spin, or click clack rattle or knock really bad.

If the lower unit is blown up, it can give you these symptoms as well though!

So you should run through this article about an engine not turning over and watch this playlist on youtube about diagnosing these issues!

The real way to tell if the motor is blown is to run a compression test or a leak-down test. And this article tells you all about the results and what they mean here!

As well as this Youtube video here:

What Causes A Powerhead To Fail?

Now what causes an outboard to powerhead to fail is a pretty big subject to cover. Because it could literally be anything!

Most commonly, an outboard powerhead failure is due to an overheat, or a lack of oil, which can cause an overheat condition.

Overheating an engine can be detrimental to the integrity of the engine. High temperatures can warp metal, melt gaskets, and through things out of alignment basically.

Which makes the engine susceptible to failure. Overheats can be caused by things like a failed water pump impeller, a failed thermostat, or a cooling system issue.

On the oiling issue, if the engine loses enough oil, it will not lubricate properly. And the machined fine tolerances of the internal engine components.

Can start wearing together, create friction, and heat each other up to the point of failure.

So low oil can also cause overheating. This can result in a bad head gasket and this will allow water into the engine where it can blow itself up!

A timing issue can also lead to an engine failure. The wrong type of fuel can cause timing issues, low octane, and other issues can also cause this.

Water ingestion will cause an outboard powerhead to fail as well. Because water does not compress.

When the piston comes up and has water in the cylinder. The water won’t compress, which will make the piston rod or some other metal component break!

Leaving you with an issue of how to repair your engine.

Outboard Powerhead Replacement Vs. Outboard Powerhead Rebuild.

When it comes to an outboard powerhead rebuild. It is a similar situation as with the lower units. For most shops, they don’t really do a lot of rebuilds.

But, because of the demand, there are a lot more, larger shops, operations, and companies that specialize in the rebuilding of powerheads.

So getting a remanned block, head, or a complete powerhead is a viable option when it comes to the rebuild situation.

These companies specialize in doing this type of work, which allows them to keep a lot of stock on hand.

Where they are rebuilding a few engines at a time of the same model. Allowing them to keep stock of the parts needed, lowering the cost of the rebuild.

Whereas your typical marina, they are just going to outsource this type of work, and just be in the business of the replacement side of things.

They will just either order you a new powerhead, whether that be a rebuild or a brand new OEM.

Though you can get into some hiccups with the OEM because some models aren’t being produced by the OEM anymore.

Leaving you with no other option. Then when they are building and selling them, they are usually a few thousand dollars more than the rebuild.

With a similar warranty period, usually only a 1-year warranty!

Now depending on the model and size of the engine, a rebuild can range from $3,500 to $12,000!

And the OEM powerhead can range from $5,000 to $16,000! Again depending on the model, whether you need a 5 HP powerhead or a 400 HP powerhead.

That will make that price vary and jump quite a bit.

When it comes to the time of the replacement though. This will usually vary from 4 hours of labor to 16 hours of labor!

Based on the engine, model, and are there other issues to deal with, as well as what kind of testing is done after the powerhead replacement has been done.

Now, powerheads generally do not come dressed. What that means is that you only get the actual block, cylinder head, and sometimes flywheel, and some sensors.

They usually come already in time, so they just need to be dressed and put onto your engine’s midsection.

Dressing means your alternators, sensors, fuel rails, ignition coils, wire harnesses, and all the other components that are required to make the engine run.

Check Us Out!

We hope that this has been insightful and allowed you to understand a little bit more about outboard engine failures, lower units, and powerheads.

Rebuilding vs. replacement, and what goes along with it!

If you have more questions or want to learn more about your boat and its different systems. You should consider joining our Boating Academy where we have created HUNDREDS of video courses teaching you basically everything about your boat!

You can also find even more helpful videos on our Youtube channel where we create even more boating videos!

And if you would like to support us to continue bringing you great content, please click the link below to Amazon where we get a commission from anything you are already going to buy! Click Here To Amazon!

Here are some other super helpful articles that you might find interesting!